Main structure and features:

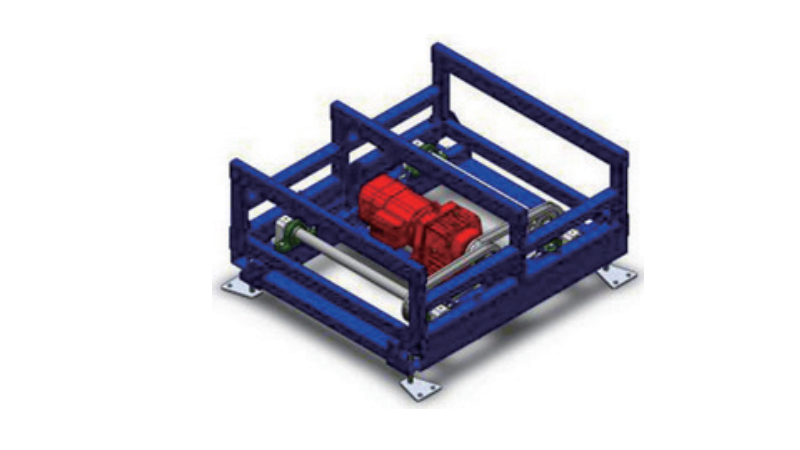

Lifting mechanism: a welded bottom frame with height adjustment feet, a base type reduction motor is placed in the middle of the bottom frame, and two shafts are connected to the bottom frame by bearing seats on both sides. The two shafts are connected to the motor through a transmission chain. Each shaft and both ends are equipped with needle roller bearings and curved arms to form a lifting structure. The four corners of the lifting frame are evenly stressed, and the lifting is smooth.

Bottom bracket: M20 screw adjustable foot fixed to the ground (two anchor bolt mounting holes).

Attachment device: photoelectric bracket (with two lifting positions and in place detection).

Purchased parts configuration: SEW is used for the reduction motor, Hangzhou Donghua is used for the chain, TR is used for the seat bearing, and Ha shaft is used for the bearing.

Surface coating: Parts such as racks and photoelectric bracket mounting plates are rust removed by wire brushes, sandpaper, etc., acid washed to remove grease, phosphated, and then electrostatically sprayed with epoxy resin powder on the surface and baked. The resin thickness is between 60μm ~ 80μm.

Formal description:

● Welded bottom frame

● R series built-in motor

● Cam lift, with a maximum stroke of 200mm

● Equipment type: Intermediate type

| Standard Style | |

| Standard | Description |

| L(mm) | L=Center distance B-100 between the drum machine/chain machine |

| H (mm) | H (min) ≥ 450 (with drum machine/chain machine H=500) |

| B (mm) | 6770 ≤ B ≤ 1520 (SEW motor); 670 ≤ B ≤ 1520 (city-state motor) |

| P (kw) | Lifting and lowering:1.5~3 |

| Lifting time(S) | 5 (Single trip) |

| Standard bearing capacity ( Kg ) | Max ≤1000Kg |

| Maximum capacity (Kg) | Max ≤1500Kg |

| Tray support foot width (mm) | Min ≥70 |

The transportation interval of unpowered drums is usually relatively short, suit···...

In the old society, everyone's transportation industry was still developing. Man···...

The unpowered drum plays a role in supporting the conveyor belt, ensuring that t···...

Power drum conveyor is a type of conveying equipment that uses the drive of the ···...

Composition of the drum:The drum is divided into two types, namely unpowered dri···...

he roller plays a fatal linking role in the roller conveyor, so the roller also ···...