Main Structure and Features:

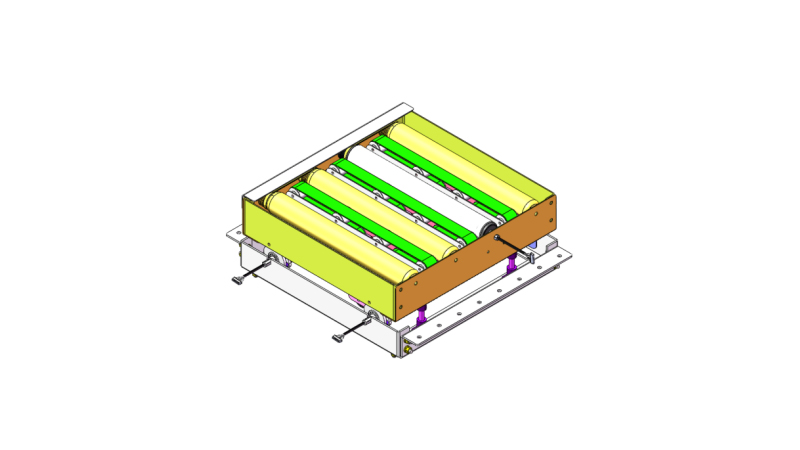

Roller conveying plate: φ50*1.5mm multi-wedge belt roller, driven by electric rollers.

Belt conveying plate: Electric rollers are used to drive multiple narrow belts.

Cam lifting roller block: Use an electric roller with cams at the end and a cam driven roller to lift the roller conveying block and the belt conveying block. While the roller conveying plate descends, the belt conveying plate rises, which reduces the jacking time and improves the conveying efficiency.

Surface coating: The fuselage, tie rods, jacking seats and other parts are first derusted by wire brushes, sandpaper, etc., and pickled to remove grease. After phosphating, the surface is electrostatically sprayed with epoxy resin powder and baked. The spraying color shall be designated by Party A.

Outsourced parts configuration: Unpowered rollers use Interroll/Dema/central shaft, electric rollers use Interroll/Dema, and multi-wedge belts use Hutchinson.

Main performance and parameters

Formal description:

● Multi-ribbed belt roller drive φ50×1.5mm

● Roller barrel Q235/201/304

● Roller spacing 75/80/100/120

● Machine life bending sheet metal

● Electric drum

| Standard Style | |

| Standard | Description |

| length L (mm) | 715(customizable) |

| height H (mm) | 170 |

| Inner width B (mm) | 350 ≤ B≤ 800(customizable) |

| Electric drum power (kw) | 0.04 |

| Conveying speed V(m/min) | V≤60 |

| Whole machine load-bearing capacity (Kg) | Max ≤50 |

| Roller spacing P (mm) | P<1/3L (L is the length of the conveyed material) |

The transportation interval of unpowered drums is usually relatively short, suit···...

In the old society, everyone's transportation industry was still developing. Man···...

The unpowered drum plays a role in supporting the conveyor belt, ensuring that t···...

Power drum conveyor is a type of conveying equipment that uses the drive of the ···...

Composition of the drum:The drum is divided into two types, namely unpowered dri···...

he roller plays a fatal linking role in the roller conveyor, so the roller also ···...