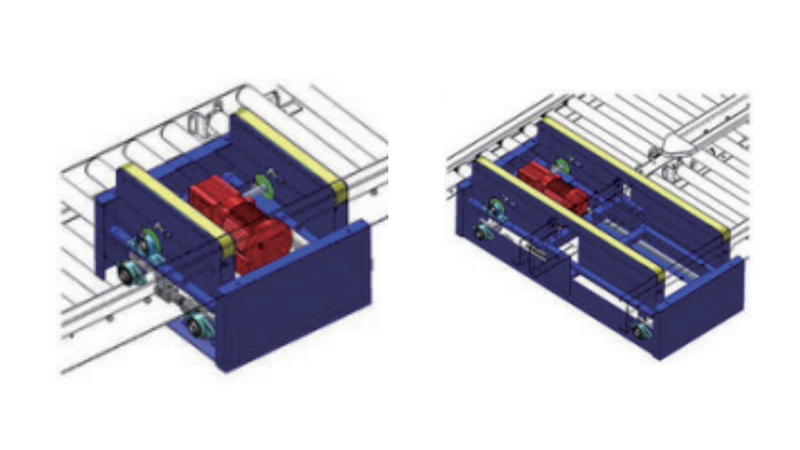

The transfer machine is a lifting and transferring device used to change the 90 ° movement direction of the luggage on the roller conveyor. Its normal state is at a low position. When the goods are transported to the transfer machine, the sensor detects that the goods are in place, and the transfer machine rises above the conveyor to transfer the goods to the adjacent conveyor. After the goods are sent out, the transfer machine descends to a low position. There are two lifting methods: pneumatic and electric.

Main Structure and Features:

Pneumatic lifting: Pneumatic lifting, a connecting rod swing mechanism driven by a cylinder, with fast and smooth lifting and lowering; Electric lifting, driven by a motor to rotate the arm shaft mechanism, causes the transplanting components to swing up and down.

Transfer mechanism: Using a transmission belt as the transfer transmission, the transmission power is driven by a built-in motor/electric drum.

Lift positioning detection: proximity switch detection.

Surface coating: Parts such as racks and mounting plates are rust removed by wire brushes, sandpaper, etc., acid washed to remove grease, phosphated, and then electrostatically sprayed with epoxy resin powder and baked. The resin thickness is between 60μm~90μm. The spraying color shall be specified by Party A on the color card.

Purchased parts configuration: SEW/SPG/Interno electric drum for reduction motor, Yongli for belt, SMC for cylinder, TR for seat bearing, and Ha shaft for bearing.

Main performance and parameters

Formal description:

● Pneumatic lift/mechanical cam lift

● One-direction sorting

● Cooperate with conveying equipment roller machine

● Conveying motor brand SPG/electric drum

● Suitable for carrier hard conveying surface

| Standard Style | |

| Standard | Description |

Center distance of roller table at installation P(mm) | P≥120mm |

| Width B (mm) | 600 ≤ B ≤ 800 |

| Sorting capacity (pieces/h) | 1000 pieces/h |

| Motor power P (kw) | 0.25 |

| Conveying speed V (m/min) | 25~40 |

| Sorting cargo weight (Kg) | Max ≤40 |

The transportation interval of unpowered drums is usually relatively short, suit···...

In the old society, everyone's transportation industry was still developing. Man···...

The unpowered drum plays a role in supporting the conveyor belt, ensuring that t···...

Power drum conveyor is a type of conveying equipment that uses the drive of the ···...

Composition of the drum:The drum is divided into two types, namely unpowered dri···...

he roller plays a fatal linking role in the roller conveyor, so the roller also ···...