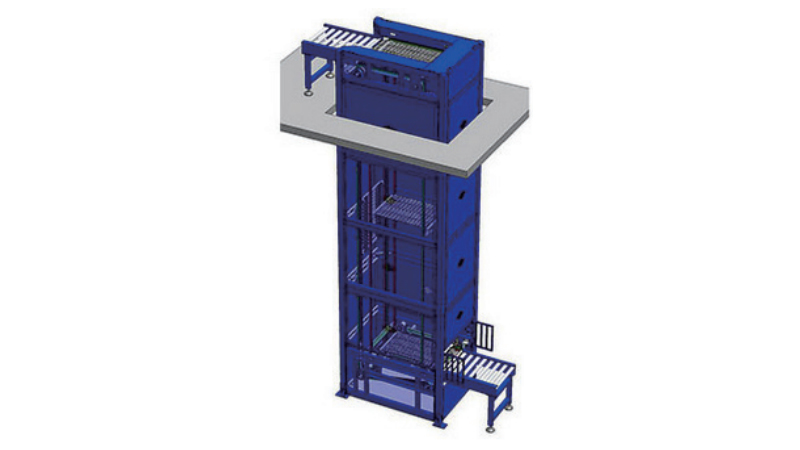

Multi continuous elevators are used for transporting goods from horizontal to vertical directions. They have the characteristics of small footprint, fast operation, quietness, and safety. Configuring conveyor lines at the entrance and exit can automatically complete the up and down transportation of goods, which can be used for the transportation of goods upstairs and downstairs in factories and logistics centers.

The Z-shaped elevator is a type of elevator that transports goods in a "Z" direction, where goods enter from one side and output from the back side in a downward to upward direction. The C-type hoist is a hoist that transports goods in the "C" direction, meaning that the import and export of goods are transported in the same direction from top to bottom.

Continuous hoist is a special equipment used for continuous lifting or descending transportation of unit cargo. Due to its chain plate return not occupying work pace and lifting space, it has the characteristics of high efficiency, low cost, and small space occupation. Compared with the spiral chain plate machine, it has a smaller footprint and lower cost. Compared with reciprocating elevators, it has high efficiency.

Applicable conveying materials: plastic turnover boxes, paper packaging, tooling boards, and hard conveying materials with continuous load-bearing surfaces on the bottom.

Main structure and features:

Body: It adopts a frame combination structure, mainly composed of three parts: upper, middle, and lower frames. The number and length of the middle frames are adjusted to meet the needs of different lifting heights. The columns in the frame are made of C-shaped cold-formed profiles, welded on one side, and then connected by bolts to form an independent frame.

Outer sealing frame: Steel wire mesh sealing frame is used.

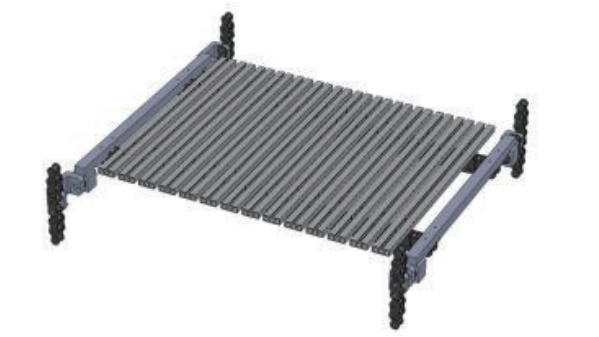

Cargo platform: The cargo platform is composed of aluminum profiles connected by pallet chains. The cargo platform is equipped with front and rear U-shaped connectors, which are connected to the lifting chain through U-shaped connectors. As the lifting chain runs, it is shown in the following figure:

Surface coating: Parts such as racks and mounting plates are rust removed by wire brushes, sandpaper, etc., acid washed to remove grease, phosphated, and then electrostatically sprayed with epoxy resin powder and baked. The resin thickness is between 60μm~90μm. The spraying color shall be specified by Party A on the color card.

Configuration of purchased parts: SEW for reduction motor, Hangzhou Donghua for chain, Dongfang Special for pallet chain, TR for seat bearing, and Ha shaft for bearing.

Formal description:

● Four-column frame type, standard mold opening column,

● Standard L=2.5m, L<2.5m;

● Modularization of standards for each framework;

● Four-chain lifting, chain specification 16A-1;

● Pallet chain specification 16A-TB 32;

● Drive the frame at the bottom of the hoist;

● Sealing frame: mesh form, connected with clip nuts;

● Used with belt conveyor

Standard Style

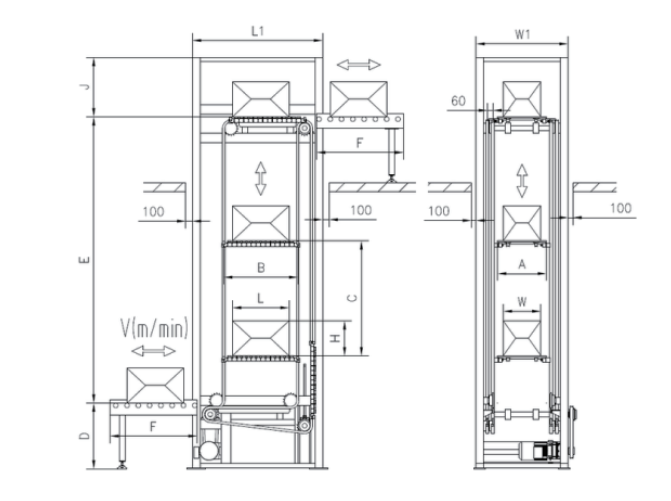

| Name | Description |

| Length of conveyed material L (mm) | L=300~1000(If 600<L ≤ 1000, the framework needs to be non-standard) |

| Width of conveyed material W (mm) | W=200~1000(If 500 < W ≤ 1000, the framework needs to be non-standard) |

| Transport height H (mm) | H≤800 |

| Lower mouth height D(mm) | D≥700(otherwise dig a pit) |

| Upper mouth and top height J(mm) | J≥H+150+122 |

| lifting stroke E(m) | E ≤ 20 (E=50 * n ≥ C, n is a positive integer) |

| Length of entrance conveyor F(mm) | F≥L+250(Entrance conveyor belt brake or obstruction) |

| Equipment length L1 (mm) | L1=1510(Standard universal) |

| Equipment width W1 (mm) | W1=1075(Standard universal) |

| Equipment height H0 (mm) | H0=D+E+J |

| Floor opening size(mm) | (L1+200)*(W1+200) |

| Pit size(mm) | (L1+450)*(W1+350) |

| Pre embedded iron size(mm) | (L1+380)* 600 |

| Motor power P (kw) | E≤8m,P=1.5B |

| 8m<E≤12m,P=2.2B | |

| Conveying speed V(m/min) | V≤40 |

| Each pallet chain carries M(Kg) | M≤50 |

| Chain length of pallet B(mm) | B=787.4 (if not standard, then B>L+180 and B is an odd multiple of 25.4) |

| Spacing between pallets C(mm) | C ≥ B+H+120 and C is an even multiple of 25.4 |

| Tray width A(mm) | A=570(if not specified, then A ≥ W+100, rounded up) |

| Increase the length of the chain linkX(mm) | Xmin=2E+2B+900,Xmax= Xmin+300 |

| X is an even multiple of 25.4 | |

| Number of chain plates Z(pieces) | Xmin/C<Z<Xmax/C,Z=Positive integer |

| (When efficiency is met, Z takes the minimum value) | |

| Transportation efficiency η | η≤60000*V/C,η<1200 Pieces/h |

| Total load(Kg) | 310Kg/m+550Kg |

The transportation interval of unpowered drums is usually relatively short, suit···...

In the old society, everyone's transportation industry was still developing. Man···...

The unpowered drum plays a role in supporting the conveyor belt, ensuring that t···...

Power drum conveyor is a type of conveying equipment that uses the drive of the ···...

Composition of the drum:The drum is divided into two types, namely unpowered dri···...

he roller plays a fatal linking role in the roller conveyor, so the roller also ···...