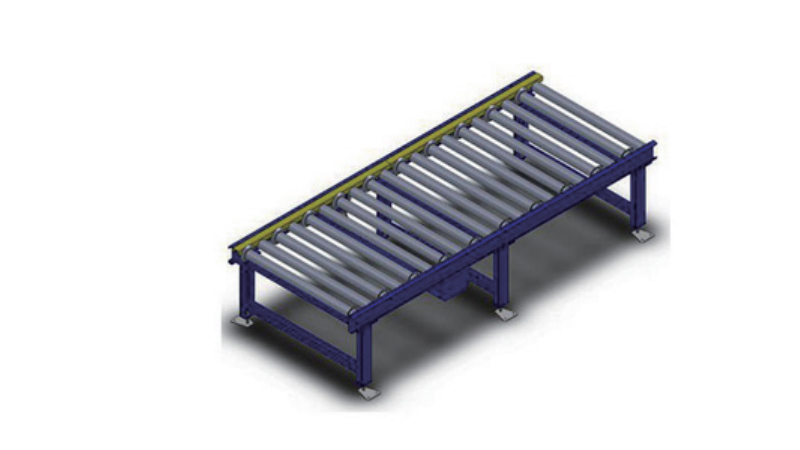

Main structure and features:

Roller: A single side double chain galvanized roller with a diameter of 76x3, with a precision rolled and welded tube body, and a roller spacing of P=167mm. The single-sided double sprocket is 10A-13T, with a diameter of 20 cold drawn carbon steel shaft. It is installed with M12 internal thread and fixed axis on the frame. The bearings at both ends of the roller are maintenance free deep groove ball bearings.

Body: The frame is made of cold-formed steel, with an outer C-shaped specification of 145X40X15X4mm. Welded support legs, bolted to the frame, with M20 screw adjustment feet fixed to the ground for a height adjustment of ± 25mm on the conveying surface.

Guiding guardrail: The tray relies on the retaining ring on the roller for conveying guidance, which is edge to side guidance. The retaining ring is welded to the roller cylinder.

Drive chain: Adopting 10A-1 precision roller chain that complies with GB1243 standard.

Drive device: Adopting an intermediate drive method, the reduction motor is installed on the bracket below the frame. It includes a base type motor with a drive sprocket. The chain connects the motor sprocket and adjacent two roller sprockets, and then the roller sprockets are sequentially connected to other driving rollers through a closed circular chain.

Protective cover: Closed protective cover for roller chain drive and motor chain drive parts.

Attachment device: photoelectric bracket.

Surface coating: Parts such as racks, legs, and photoelectric bracket mounting plates are rust removed by wire brushing, sandpaper, acid washing, and degreasing. After phosphating, the surface is electrostatically sprayed with epoxy resin powder and baked. Fasteners with resin thickness between 60 μ m and 90 μ m.

Purchased parts configuration: SEW is used for the reduction motor, and Hangzhou Donghua is used for the chain.

Formal description:

● Double chain drive drum (10A-13Z) with a diameter of 76 × 3mm

● Roller retaining ring guide

● Rack steel 125 × 70 × 15 × 5mm (drive side)

● Rack steel 125 × 70 × 15 × 4mm (non drive side)

● Roller spacing 166.7mm

● Series built-in motor

| Standard Style | |

| Standard | Description |

| Length L (mm) | 850 ≤ L ≤ 8000 |

| Height H (mm) | H(min)≥380 |

| Chain center distance B (mm) | 620 ≤ B ≤ 1520 |

| Motor power P (kw) | 0.37~0.75 |

| Conveying speed V (m/min) | V=12 V=16 V=18 |

| Whole machine load-bearing capacity (Kg) | 15 (according to 1200 pallets, 12m/min conveying speed) |

| Whole machine load-bearing capacity (Kg) | Max ≤1500Kg |

| Tray support foot width (mm) | Min ≥70 |

The transportation interval of unpowered drums is usually relatively short, suit···...

In the old society, everyone's transportation industry was still developing. Man···...

The unpowered drum plays a role in supporting the conveyor belt, ensuring that t···...

Power drum conveyor is a type of conveying equipment that uses the drive of the ···...

Composition of the drum:The drum is divided into two types, namely unpowered dri···...

he roller plays a fatal linking role in the roller conveyor, so the roller also ···...