Main structure and features:

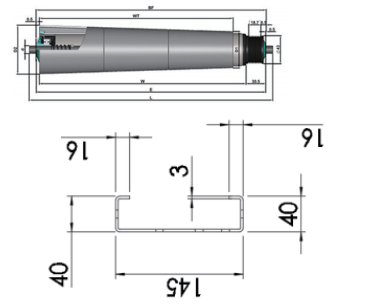

Roller: φ50*1.5mm multi-wedge belt roller, bearings at both ends are maintenance-free deep groove ball bearings, barrel material is carbon steel galvanized, and is covered with hard plastic cone sleeves.

Frame: Laser cutting/welding is used for blanking of 3mm steel plate, size: 145* 40mm, and the structure is as shown in the figure:

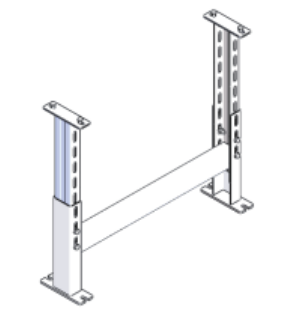

Leg: Made of customized profile welding, it has the advantages of firmness and good stability. Connect the connecting plate to the frame bolt, adjust the foot base to connect with the ground, and adjust the height of the conveying surface by ± 50mm. The structure is shown in the figure:

Drive device: motor-driven.

Surface coating: Components such as frames, legs, guides, accessories, etc. are first derusted with wire brushes, sandpaper, etc., and then acid washed to remove grease. After phosphating, the surface is electrostatically sprayed with epoxy resin powder and baked. The spraying color shall be specified by Party A on the color card.

Outsourced component configuration: Electric drum drive/JSCC/SPG motor drive, lifting belt adopts Hutchinson.

Main performance and parameters

Formal description:

● Multi-ribbed belt roller drive/φ50×1.5mm

● Roller barrel Q235/201/304

● Conical roll form Plastic cone sleeve/steel type

● Frame steel 125×40×3mm

● Built-in electric roller/SPG built-in motor

| Standard Style | |

| Standard | Description |

| Steering angle θ ( ° ) | 90/60/45/30 |

| Turning radius R (mm) | 850 |

| Height H (mm) | H(min)≥300 |

| Inner width B (mm) | 350 ≤ B ≤ 800 |

| Motor power P (kw) | 0.06~0.2 0.032 (Electric roller) |

| Conveying speed V (m/min) | V=20 V=25 V=32 V=55 |

| Conveying capacity ( Kg/m ) | Max ≤50 |

| Roller angle θ ( ° ) | Max 5 |

| Roller spacing P (mm) | P<1/3L(L is the length of the conveyed material) |

The transportation interval of unpowered drums is usually relatively short, suit···...

In the old society, everyone's transportation industry was still developing. Man···...

The unpowered drum plays a role in supporting the conveyor belt, ensuring that t···...

Power drum conveyor is a type of conveying equipment that uses the drive of the ···...

Composition of the drum:The drum is divided into two types, namely unpowered dri···...

he roller plays a fatal linking role in the roller conveyor, so the roller also ···...